TOGETHER

WE CAN RESTORE

THE PLANET

hydroponic is good

water efficency turnover of -10%

hydroponic grow requieres less space and gives better yields

Hydroponic offers longer shell life than soil grown

Are used to provide better nutrition

harvest, sale and delivery all 52 weeks of the year

no use of agrochemicals

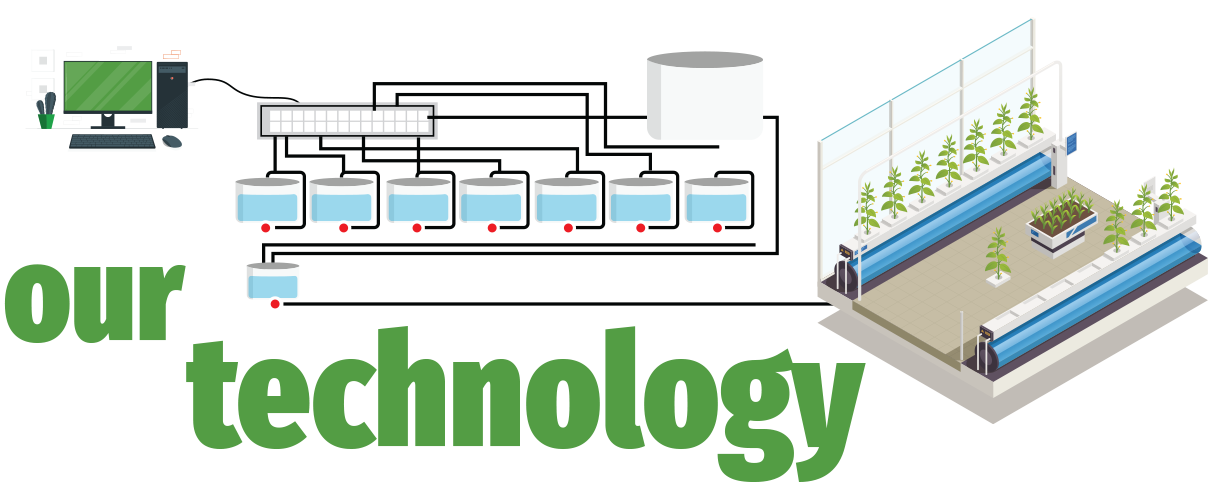

Our greenhouses use automated technology to create the perfect environment for our peppers. We ensure optimal growth without adversities with precise irrigation, climate controls, and efficient nutrient delivery. This eco-friendly approach not only enhances productivity but also supports a sustainable future.

Our commitment begins in the nursery, where the plants that will give life to our peppers are sown. When ready, they are transplanted to our high-tech greenhouses, developing for months under careful attention.

Instead of using agrochemicals, we employ biological control by introducing beneficial organisms that help manage pests, keeping our plants healthy and producing specialty peppers of the highest quality and freshness.

We use custom software to track every stage of our peppers' journey, monitoring conditions and processes to ensure high product quality and consistency from greenhouse to table.

The irrigation system, dosage and control of nutrition parameters is established under the Priva Office Compact CC software, offering the highest security and reliability of dosage.

We take care daily that the levels of nutritive solution and ph are ideal, monitoring with frequency the drainage levels of our substrate, generating balances and adjustments to optimize the water and the solution provided through our irrigation system.

In hydroponic crop, the essential first and foremost is the means of transport of nutrients, also, the water, which plays a vital role in the maintenance of the soil.

Through our fertilizer injection system, we design each of the amounts of nutrients necessary for the correct growth and development of the plants in the greenhouse.

The layout and agronomic design of our crop within the greenhouse is based on yield metrics and weekly evaluations of physiological parameters, which provide the guideline to generate different actions to be taken in order to offer quality products to the market.

Controlador de riego.

La programación temporizada de cada uno de los riegos, dosificación y control de parámetros de nutrición se establece bajo el software Priva Office Compact CC, ofreciendo la más alta certeza y confiabilidad de dosificación 2 3 4 5 principales.

Sistema hidropónico.

Cuidamos día a día, que los niveles de solución nutritiva y pH sean los ideales, monitoreando con determinada frecuencia los niveles de drenaje de nuestro sustrato, generando balances y ajustes para optimizar el agua y la solución aportada a través de nuestro sistema de riego.

Reservorio de agua limpia.

En la actividad de un cultivo hidropónico, lo esencial ante todo es el medio de transporte de los nutrientes, el agua, la cual desempeña la vital función de mantener.

Sala de fertirriego.

Diseñar cada una de las cantidades de nutrientes necesarios para el correcto crecimiento y desarrollo de las plantas en el invernadero, y su disposición dosificada tiene lugar en nuestro sistema de inyección de fertilizantes, en el cual se lleva el control diario de parámetros deseados de conductividad y pH de la solución nutritiva.

Invernadero de producción.

La programación temporizada de cada uno de los riegos, dosificación y control de parámetros de nutrición se establece bajo el software Priva Office Compact CC, ofreciendo la más alta certeza y confiabilidad de dosificación.

At hyfood, we believe technology and nature can work together. Our hydroponic greenhouse are proof of this: innovation that respects and protects the environment while ensuring the highest quality food.

smart greenhouses for a

greener tomorrow

Copyright © 2024 HyFood. All rights reserved.